The absorption and diffusion of sweat directly affect the comfort performance of clothing. Testing this performance is particularly important, especially the sports fabric. At present, AATCC 195, GB/T 21655.2 has defined how to test the transfer characteristics of sweat in cloth. 290B fully meets the test standard for measuring the overall dynamic performance of liquid in knitted fabric, and mainly tests the following aspects:

1. Absorption speed - the water absorption time on the front and back of the fabric.

2. One way transfer capacity is the difference between the absorption and diffusion of liquid on two surfaces.

3. Diffusion / drying speed - the velocity of the liquid diffusion at the two surface of the fabric.

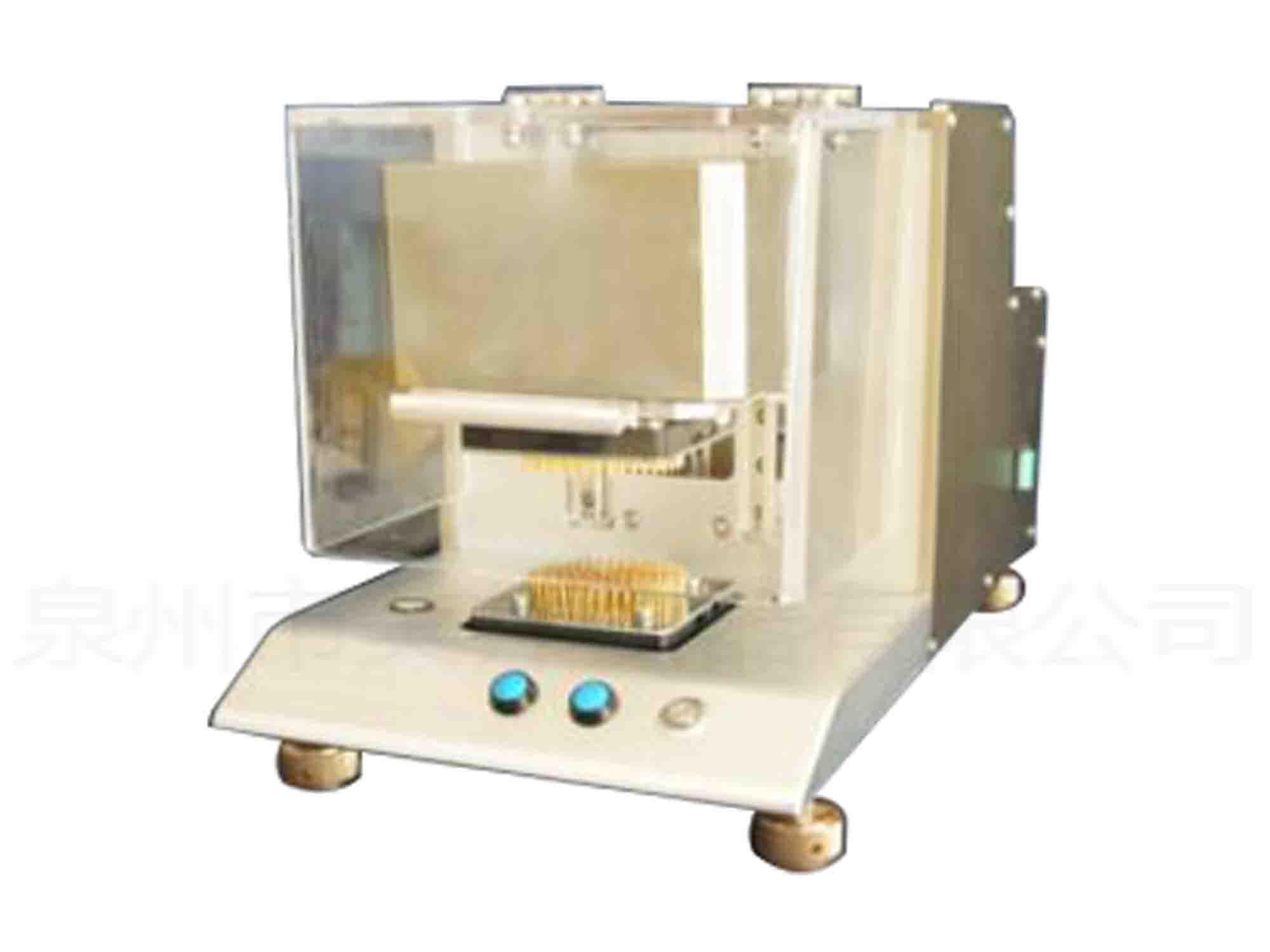

The instrument consists of a pair of upper and lower multiring resistance measuring probes. The stepper motor drives the upper sensor to press the sample horizontally on the lower conveyor with fixed pressure, and then transfers 0.2 grams of standard test solution to the surface of the sample evenly in 20 seconds. The computer can dynamically record the changes of the resistance of each loop, and through the standard calculation formula, we can get all the parameters we need.

The instrument can measure the following parameters:

1. Upper / lower wetting time (WTT/WTB).

2. Upper / bottom absorption speed (TAR/BAR).

3. Upper / bottom maximum diffusion radius (MWRt/MWRb).

4. Upper / lower liquid perspiration rate (TSS/BSS).

5. Accumulation of one-way transmission capacity (R).

6. The overall liquid moisture absorption and diffusion capacity (OMMC).

AATCC 195,GB/T21655.2

1. The shell is all metal structure, and it has good anti-interference ability to the external interference signal.

2. The test sensor moves up and down from manual to automatic. The upper sensor is driven by stepper motor, and the built-in pressure detection device moves to the fixed pressure to stop automatically. After the test is finished, it automatically returns.

3. The pump structure is improved, the pump water is uniform and stable, and the pump volume can be adjusted by software. The pump can rotate backward, and the brine in the pipe can be pumped back to the liquid storage tank, so as to prevent the brine crystallization from blocking the pipeline.

4. The wireless wifi connects the computer, and the data transmission is more stable and reliable.

×

×

閩公網(wǎng)安備 35058302350905號(hào)

閩公網(wǎng)安備 35058302350905號(hào)